New Global Launch: Atomrobot Releases Overseas Version of Cobot Palletizer Workstation

As global manufacturing accelerates its shift toward intelligent and flexible production, collaborative robots are rapidly becoming a core growth segment in industrial automation. According to Interact Analysis, the global cobot market exceeded USD 1.4 billion in 2023, with logistics and warehousing accounting for over 30%.

As one of China’s leading industrial robot manufacturers, Atomrobot has introduced a full portfolio of cobot palletizer tailored for overseas markets, right as its palletizing applications mature domestically. This move marks not only a global breakthrough for Chinese smart manufacturing in high-end industrial equipment but also brings “extreme efficiency + flexible deployment” to empower automation abroad and boost competitiveness.

Three Series, Seven Models – A Technological Upgrade

Markets in Europe, the U.S., and Southeast Asia are facing dual challenges: rising labor costs and shortages are pushing enterprises to accelerate automation, while multi-category, small-batch production demands greater equipment flexibility. Traditional industrial robots, hindered by long deployment cycles, complex programming, and large footprints, struggle to meet the needs of industries with frequent product changes such as food, pharmaceuticals, and personal care.

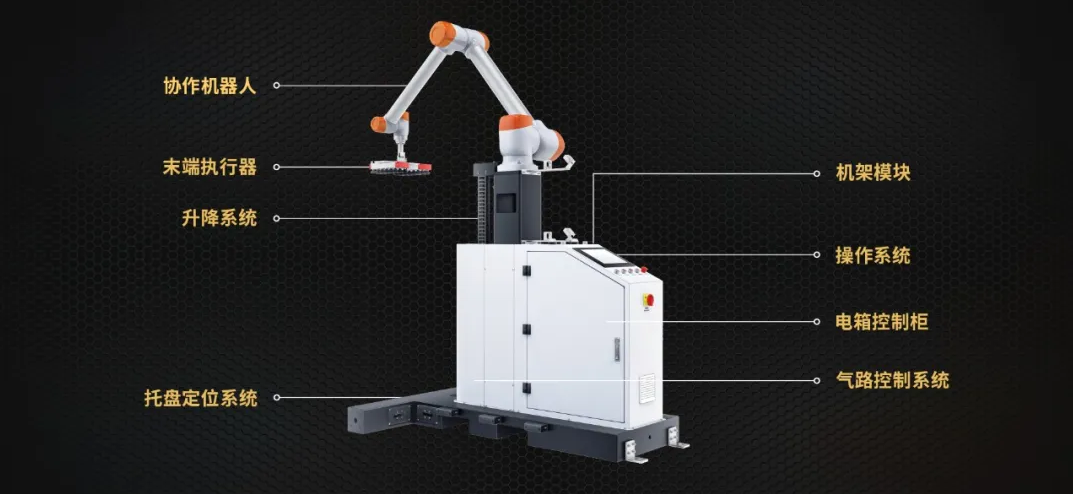

Targeting this structural gap, Atomrobot has launched three overseas cobot palletizing series (AM-20 to AM-40), comprising seven models. Built around a plug-and-play concept, the modular robot design drives flexible upgrades across entire production lines:

- Core configuration: Panasonic motors and drivers, premium reducers, and Atomrobot’s self-developed AI high-speed motion control system deliver exceptional performance.

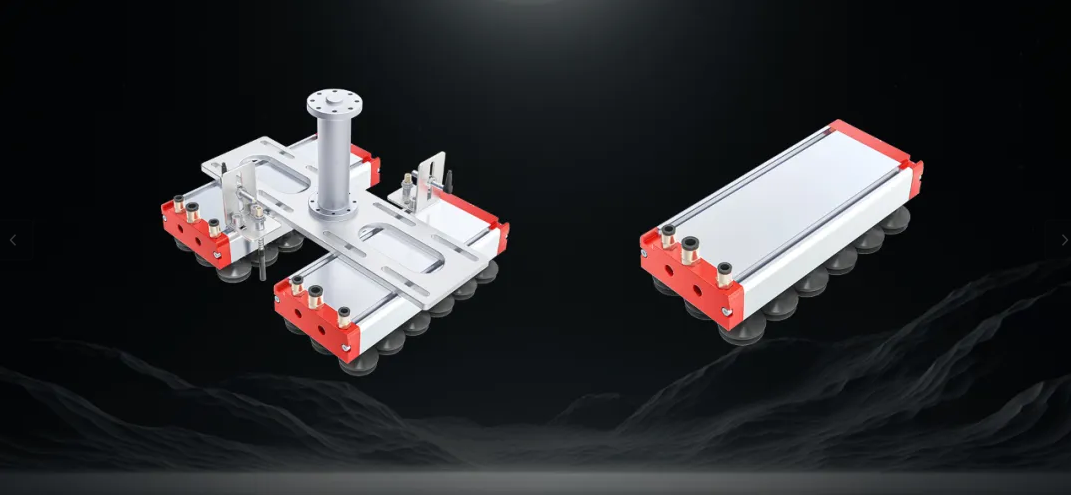

- End-of-arm tooling: Atomrobot’s integrated lightweight suction gripper (1.9kg each), powered by a high-flow vacuum generator (air consumption 240L/min, max flow 720L/min, vacuum -72Kpa, theoretical suction 26kg).

- Operating system: Intuitive visual programming interface, learnable in just 30 minutes.

- Pallet positioning: Lidar + inclined roller conveyor for full auto-alignment of 1200×1200mm pallets.

- Safety: High-precision force sensor with 10 collision levels; Lidar + safety fencing stops the robot within 0.1s.

- Mobile base: Compatible with pallet jacks/forklifts for flexible workshop layouts.

Compared with traditional solutions, Atomrobot’s overseas models respond faster, are easier to operate, deploy more flexibly, and apply more broadly:

- Deployment cycle cut by 90%: Installation and commissioning in 2 hours, training completed in half a day.

- Changeover efficiency ×20: 5-minute switch for new stacking patterns, supporting 800+ preset trajectories.

- Overall costs down 40%: ROI in 10–18 months, footprint reduced by 60%.

Most notably, its dual-product mixed palletizing and label orientation recognition functions meet strict batch management requirements in pharmaceuticals and food, while its 2300mm stacking height surpasses the safety limits of manual operations.

From Standardization to Customization – Industry-Wide Coverage

Thanks to innovation and strong cost-effectiveness, Atomrobot cobot palletizers are winning broad adoption. Its payload range has expanded from 20kg to 40kg, with major upgrades in stability and precision as well as stronger human-robot collaboration. Combined hardware and algorithm coordination enables complex “palletizing + depalletizing” workflows.

- Hardware industry – Closed-loop palletizing & depalletizing:

For a fastener giant, Atomrobot deployed the AM-30 to automate the full cycle of suction depalletizing, barcode scanning, and re-palletizing. Efficiency jumped from 5 to 12 boxes/min (20kg each), cutting labor costs by 70%. Fence-free design saved 15% of shop floor space, while the graphical interface allowed workers to adjust stacking patterns directly.

- Pharmaceutical industry – High-stacking solution to warehouse bottlenecks:

The AM-20, equipped with a lift arm and automated pallet library, reached stacking heights of 2100mm. Combined with closed-loop data management, storage density rose by 30%. One pharma company reduced staffing from three operators to a single floating worker while eliminating package damage caused by manual handling.

- Food industry – High-speed mixed line palletizing:

For a global food brand, Atomrobot’s AM-20 executed dual-line palletizing, switching between single/double/triple gripping for 4–10kg cartons, reaching 16 boxes/min. The solution cut outsourced labor needs by 80% and resolved seasonal labor fluctuations.

ROI Analysis and Hidden Value Creation

From “labor shortage” to the “lights-out factory” era, Atomrobot’s cobot palletizers are reshaping the economics of industrial automation. Their ease of use lowers automation barriers, while flexible productivity empowers SMEs to upgrade. By driving technology innovation from real-world needs, Atomrobot is helping companies write a more compelling financial story.

For example, at a Southeast Asian personal care plant deploying two AM-30 units:

Tangible cost savings:

- Labor replacement: 4 fixed positions eliminated, saving USD 120,000 annually.

- Efficiency gains: Speed increased from 8 to 14 boxes/min, boosting daily capacity by 25%.

- Reduced downtime losses: Collision detection cut equipment damage by 90%, saving USD 30,000 annually in maintenance.

Hidden value unlocked:

- Flexible response: Product changeover time dropped from 4 hours to 15 minutes.

- Safety compliance: CE certification avoided fines for overseas safety violations.

Result: Payback achieved in just 10 months, compared to 18+ months for traditional industrial robot solutions.

Local Adaptation and Global Ecosystem Building

Centering on “technology fit + ecosystem co-building,” Atomrobot is embedding deeply into overseas manufacturing ecosystems. With CE certification, its overseas cobot palletizers fully comply with EU Machinery Directive (MD) and EMC Directive standards, ensuring safety, reliability, and sustainability for the European market.

In Europe and the U.S., Atomrobot is promoting high-payload models like the AM-40-G to serve automotive and heavy machinery palletizing needs. In Southeast Asia, it is enhancing AM-20 with anti-humidity and anti-seismic designs to withstand tropical climates, while offering attractive price-performance ratios to food and pharma industries.

Currently, Atomrobot’s overseas customers include multinational giants such as Mengniu, Panasonic, and Haidilao. With global manufacturing pursuing intelligence and cost optimization, Atomrobot’s cobot palletizers are set to benefit further—feeding back into the market and reinforcing their leadership.